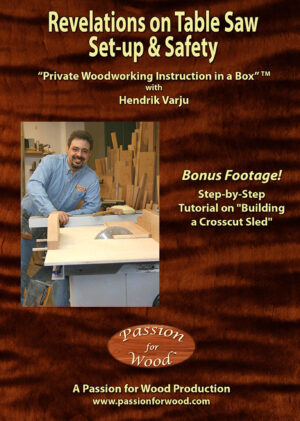

SHARPENING & TUNING HAND PLANES AND CHISELS DVD

$120.00

with Hendrik Varju

Produced by Passion for Wood, Ontario, Canada

As reviewed in The Australian Woodworker Issue 167

A story attributed to Stirling Moss, the 1950’s British racing driver, tells of the time when he allowed an enthusiastic, but inexperienced, driver to take his car for a spin. He said afterwards that even as his car fish-tailed out of the pits, he was aware that he had made a serious mistake. As it happened, the car and driver arrived back in one piece, but not before causing a good deal of consternation for everyone at the racetrack.

The problem was that although the loaned vehicle had the normal four road wheels, as well as its controls in their usual locations, its performance was so far removed from that of a normal car, that a novice might easily, though inadvertently, cause it injury.

To see something akin to this in a woodworking environment, you have only to walk into a professional woodworker’s workshop, idly pick up what is clearly a favourite handplane and start looking for a piece of wood to plane.

A handplane, as Hendrik Varju is at pains to demonstrate in this comprehensive DVD presentation, does not come straight from the retailers, ready to work. It must be carefully fettled – a process that may take as little as an hour or two for a high quality, high priced plane, or significantly more than a day for a less expensive tool.

This fine tuning converts an assembly of parts into a cohesive whole that generally needs just gentle guidance to cut evenly and smoothly. Because the work must usually be carried out only once, the routine maintenance of the plane is reduced to little more than a light honing of the cutting edge.

While the handplane is the primary focus of these DVDs – since it is the more complicated of the two – preparation of the woodworking chisel is also considered in detail.

Varju begins with an overview of the procedures involved, remarking first on the need to remove any oil or lacquer applied by the manufacturer. The purpose of this coating is to protect the tool during transit from the factory to the user. Oil can be cleaned off with paint thinners, but lacquer is more difficult to remove.

He shows how chisels may be stood in lacquer thinners while handplanes must be washed down carefully (to avoid damage to paint or plastic surfaces) and then disassembled and cleaned afterwards.

Next comes an examination of the structure of a plane, showing how the frog is mounted within the body and remarking on how any misalignment will affect the plane’s performance.

Later, Varju suggests an ingenious method of using epoxy and wax to effect a permanent repair should the frog be poorly supported by the body casting.

The need to grind a back bevel on the cap iron or chipbreaker is often overlooked by users of less expensive planes. But if this is not done, the sometimes poor contact between this component and the back of the blade, can easily lead to vibration which will in turn affect the cutting action of the plane. Varju shows how to grind the back bevel accurately with minimal effort.

Grinding a back bevel on the front edge of the mouth of the plane is also recommended. The purpose of this is to encourage the curling of the shaving away from the blade, up into the body of the plane. In showing how this is done, Varju also demonstrates his own meticulous approach when he notes that the grinding must leave a short vertical section at the extreme edge of the sole so as to ensure that the width of the mouth is not altered.

This operation is followed by the grinding of the lever cap which is necessary in order to increase the area of firm contact between it and the chipbreaker.

Only when all of this work has been carried out, does Varju suggest beginning to flatten and smooth the sole of the plane.

Here, he introduces a variety of methods from commercially available lapping plates to marble slabs, plates of glass and diamond ‘stones’.

He discusses each of them in turn, giving their advantages and disadvantages and shows his preferred methods for their use.

Now he gives attention to the blade, beginning with the flattening of the back of both chisels and plane blades.

The third DVD is devoted entirely to Effective Cutting Angles and Hollow Grinding while the fourth discusses Honing Guides versus Free-hand Honing and Free-hand Honing Technique.

Varju uses a grinding jig (which he demonstrates) but prefers free-hand honing. Nevertheless, he shows many of the honing guides that are currently on the market and discusses their pros and cons.

The fifth DVD contains ‘Bonus Footage’ on Cambered Edges as well as interesting comments on topics such as the choice of handplanes, the diminishing return from sharpness and money versus time.

The presentation techniques employed in this series are similar to those in Varju’s past 8 videos. He begins with scenes of the country surrounding his workshop, studio and school which is located just outside Toronto, in Canada. Once inside, he appears, cup of coffee in hand, welcoming the viewer as if he or she were a student in one of his classes.

This is obviously the ambience he wishes to create – a relaxed atmosphere in which he can talk conversationally, covering the subjects in a manner that makes it easy to assimilate the information he presents.

Most ‘classes’ begin with an array of tools and equipment on a bench while to one side there is an easel on which is clamped the drawing paper Varju uses to write and draw as he illustrates each point as it is raised.

The result is a set of deliberately orchestrated, but easily absorbed, lessons in preparing handplanes and chisels for use.

Over the past seven years, this style has earned Hendrik Varju a formidable international following. A feature of his presentations is that they are clearly based on experience in his own workshop. The material is therefore practical and immediately useful.

But perhaps more important is that he discusses procedures that parallel those that he recommends, so that the viewer can confidently choose the most appropriate methods for use in his or her own workshop.

Duration: 523min, 5 discs

DVD – English – NTSC