THE AUSTRALIAN WOODWORKER

THE AUSTRALIAN WOODWORKER

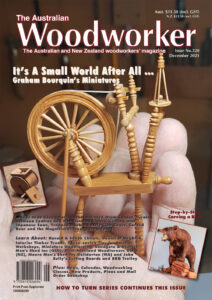

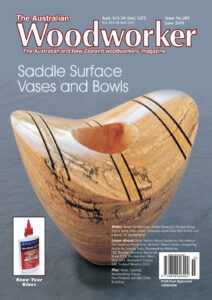

Skills Publishing has been proudly producing The Australian Woodworker since 1985, making it the second oldest woodworking magazine in the world.

Devoted to woodworkers and hobby cabinetmakers, members of Men’s Sheds, Women’s Sheds and Woodworking Clubs across Australia and New Zealand, as well as all others wanting to know more about all forms of woodworking – from turning and joinery to pyrography, intarsia, carving and all other forms of woodcraft – The Australian Woodworker has faithfully served its diverse audience for nearly 40 years.

Devoted to woodworkers and hobby cabinetmakers, members of Men’s Sheds, Women’s Sheds and Woodworking Clubs across Australia and New Zealand, as well as all others wanting to know more about all forms of woodworking – from turning and joinery to pyrography, intarsia, carving and all other forms of woodcraft – The Australian Woodworker has faithfully served its diverse audience for nearly 40 years.

As the late founding publisher, Art Burrows, stated in the editorial of the first issue of AWW … “a magazine for such a wide audience must necessarily cover a wide range of topics. But throughout the articles which appear in this magazine, now and in the future, we hope you will recognise a single theme – summed up by the statement ‘to pursue excellence on a budget’. To help you do your best work, with the best tools you can reasonably afford … these are the basic editorial objectives of The Australian Woodworker. And, hopefully, to entertain”.

Published bi-monthly, every issue features a wide gamut of projects, technical tips, information on new products, reviews, profiles of woodworkers and Woodworking Clubs/Men’s and Women’s Sheds, an events calendar, woodworking classes across the country, local and International news, a directory of advertisers’ services, classifieds and much more.

Published bi-monthly, every issue features a wide gamut of projects, technical tips, information on new products, reviews, profiles of woodworkers and Woodworking Clubs/Men’s and Women’s Sheds, an events calendar, woodworking classes across the country, local and International news, a directory of advertisers’ services, classifieds and much more.

For the current issue, printed back issues from 201 onwards, back issues 1 to 200 on USB, and to arrange an annual subscription, plus rates and specs, click HERE

WOODWORKING PLANS

Skills Publishing is the seller of the largest inventory of in the country. It is the Australian stockist of UBild plans (for everything from models vehicles to furnishings, décor items, children’s toys, clocks, rocking horses, Christmas and more).

We also stock a select range of Australian Designer Neil Scobie’s plans, David Bryant and traditional Ashby English plans, a selection of traditional and contemporary American furniture plans produced by famous American designer/makers, and the late Les Miller’s popular bench plan.

To see and select from the huge range of Woodworking Plans available, click HERE

BOOKS AND DVDS

BOOKS AND DVDS

Woodworking books and DVDs have long been a staple of the Skills Publishing enterprise. Though a range of titles are no longer available through the online store, this is still an inventory of titles available, ranging from works on carving and furniture to titles dealing with woodturning, finishing, tools and workshops and more. There’s a range of specials currently available too.

For further details and to purchase Books and DVDs, click HERE

THE TIMBER BUYER’S GUIDE

THE TIMBER BUYER’S GUIDE

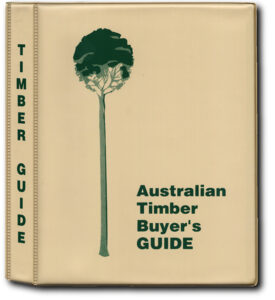

The Timber Buyer’s Guide – now in its fourth reprint – was originally released as a collection of the ‘Woodie’s Guide To Woods’ articles published in The Australian Woodworker magazine. Compiled in a ring binder format, each page is dedicated to a timber species and contains a colour plate and detailed notes about the working properties of the timber. The original edition of the Timber Buyers Guide contains 63 of Australia’s most commonly-purchased timbers with five looseleaf sets of 9 additional timbers each set also available to add to the Guide.

For further details and to purchase the Timber Buyers Guide, click HERE

THE AUSTRALASIAN TOYMAKER

THE AUSTRALASIAN TOYMAKER

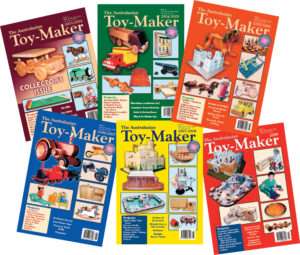

Dedicated to the toymaker, six issues of The Australasian Toymaker were produced from 2003 to 2009. An essential resource for wooden toymakers of all skill levels and interests, the magazine features projects as diverse as models and castles, dolls houses and miniature furniture, novelties and children’s curios, wooden games and much more. The magazine can be purchased separately or grab all six collector editions.

For further details and to purchase The Australasian Toymaker, click HERE

Banner image ‘Shavings’ courtesy Sophie Heard – Sophie’s Spoons